Why A Rug Pad May Contain Adhesives

Most rug pads found today contain some sort of adhesives. Manufacturers use the adhesives as a cost saving method towards the performance of their rug pads, yet this compromises quality and protection.

The rubber in our Ultra Premium is heat pressed to the felt. This eliminates the use of dangerous and damaging adhesives that are found in most other rug pads.

Felt Rug Pads and Adhesives

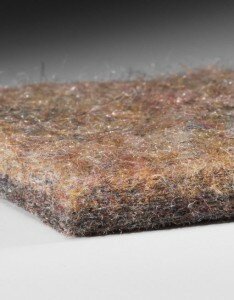

Felt rug pad is compressed into a certain density when it is being manufactured. Once out of the press, the padding looks fuzzy because of the nature of the material. The manufactures then apply a clear adhesive to each side of the pad. This adhesive dries and keeps the felt intact and prevents it from shedding. Unfortunately, this same adhesive can harm the floor, cause an odor and off-gas.

Non Slip Rug Padding and Adhesives

Most of us have seen the mesh or waffle looking rug pads in many stores. These are the pads with holes in them and have come to be known as non slip pads. Most people also refer to these thinner pads as rubber rug pads. The fact is that these pads are made of plastic and normally come from China. During the manufacturing process, an adhesive is applied to the padding. The intent of the adhesive is to give the pad a non slip function. The adhesive is sticky to the touch and actually adheres to the floor to prevent rug slipping, hence the phrase non slip rug pad. Here, again, the problem with the adhesive is that it causes damage to the floor, smells and will off-gas combined with the plastic.

The other type of non slip rug pad, the felt and rubber one, is made in such a way that the rubber is attached to the felt with glue or adhesive. This is proven to cause harm to the floor and, depending on its use, can actually break down and have a short lifespan. If any water or liquid is spilled on the pad, the mixture with the adhesive within the pad can cause very negative results.

The main reason why manufacturers use adhesives on their rug pads is based on a cost factor. Using commercial adhesives to keep rug pads together or to allow them to prevent slipping costs much less money than the alternative method of production, mainly using heat pressing instead. Heat pressing is more time consuming and costs more than simply applying a coating of adhesive to the rug pad, so this is not an attractive process to most manufacturers.

How to Avoid Adhesives in Rug Pads

At Rug Pad Corner, we do not believe in the use or application of any adhesives or chemicals to our rug pads. To keep the felt intact in Superior Rug Pad, we utilize an intense heat pressing process that actually presses the felt together without the use of glue or adhesive. Ultra Premium contains a solid layer of natural rubber that is also heat pressed to the felt. Our Super Hold rubber rug pad, a look-a-like to the popular mesh looking pads, is made of all natural rubber. Since rubber naturally adheres to surfaces, there is no need to apply a sticky adhesive to allow it to prevent rug slipping. All of our rug pads are made with the materials they are described with and without any adhesives or glue.

Since you have many choices in rug pads today, you may settle for one of the many containing adhesive, yet you do not have to. Visit rugpadcorner.com for natural felt and rubber rug pads made the old fashioned way and meant to last and perform in the safest possible manner.

INTERNATIONAL SHIPPING

INTERNATIONAL SHIPPING